Nothing ruins a relaxing shower quite like a sudden blast of cold water. If you’re dealing with intermittent hot water from your tankless water heater, you’re not alone. This frustrating problem affects countless homeowners and can stem from several different causes. The good news is that many of these issues are diagnosable and fixable with some basic troubleshooting knowledge.

Understanding why your tankless water heater loses hot water during a shower starts with recognizing that these on-demand systems operate differently than traditional tank models. They heat water instantly as it flows through the unit, making them sensitive to factors like water flow rate, pressure fluctuations, and various mechanical components that can interrupt the heating process.

A Cold Surprise: Instant Answers to Your Tankless Heater Shutdown

When your tankless water heater suddenly goes cold mid-shower, several common culprits are typically to blame. The most frequent causes include insufficient gas supply, overloaded demand, and mineral buildup that interferes with the unit’s heating capacity.

One phenomenon many homeowners experience is the “Cold Water Sandwich” effect. This occurs when your tankless unit starts up after being idle, initially delivering hot water that’s followed by a burst of cold water before returning to the desired temperature. This happens because residual hot water in the pipes gets delivered first, followed by cold water that hasn’t been heated yet, and finally the properly heated water as the system reaches full operation.

Quick identification checklist:

- Does the cold water occur immediately or after several minutes of hot water?

- Are multiple fixtures running simultaneously?

- Has your water pressure seemed lower recently?

- When was the last time you performed maintenance on your unit?

Flow Rate Issues and Minimum Activation Thresholds

Tankless water heaters require a minimum flow rate to activate their heating elements. Most units need between 0.5 to 0.8 gallons per minute (GPM) to trigger the heating process. When water flow drops below this threshold, the unit automatically shuts off, resulting in cold water.

Several factors can cause flow rate problems:

Low Water Pressure

If you’re experiencing water pressure problems throughout your home, your tankless heater may not receive adequate flow to maintain operation. Pressure fluctuations during peak usage times can cause the unit to cycle on and off intermittently.

Partially Closed Valves

Check that all valves leading to and from your tankless unit are fully open. A partially closed isolation valve can reduce flow rate enough to cause shutdown issues.

Clogged Aerators and Showerheads

Mineral deposits in your showerhead or faucet aerators can restrict water flow, preventing your heater from reaching its minimum activation threshold. Regular cleaning of these components helps maintain proper flow rates.

For homes with consistently low water pressure, installing a water pressure booster pump can provide the consistent flow needed for reliable tankless operation.

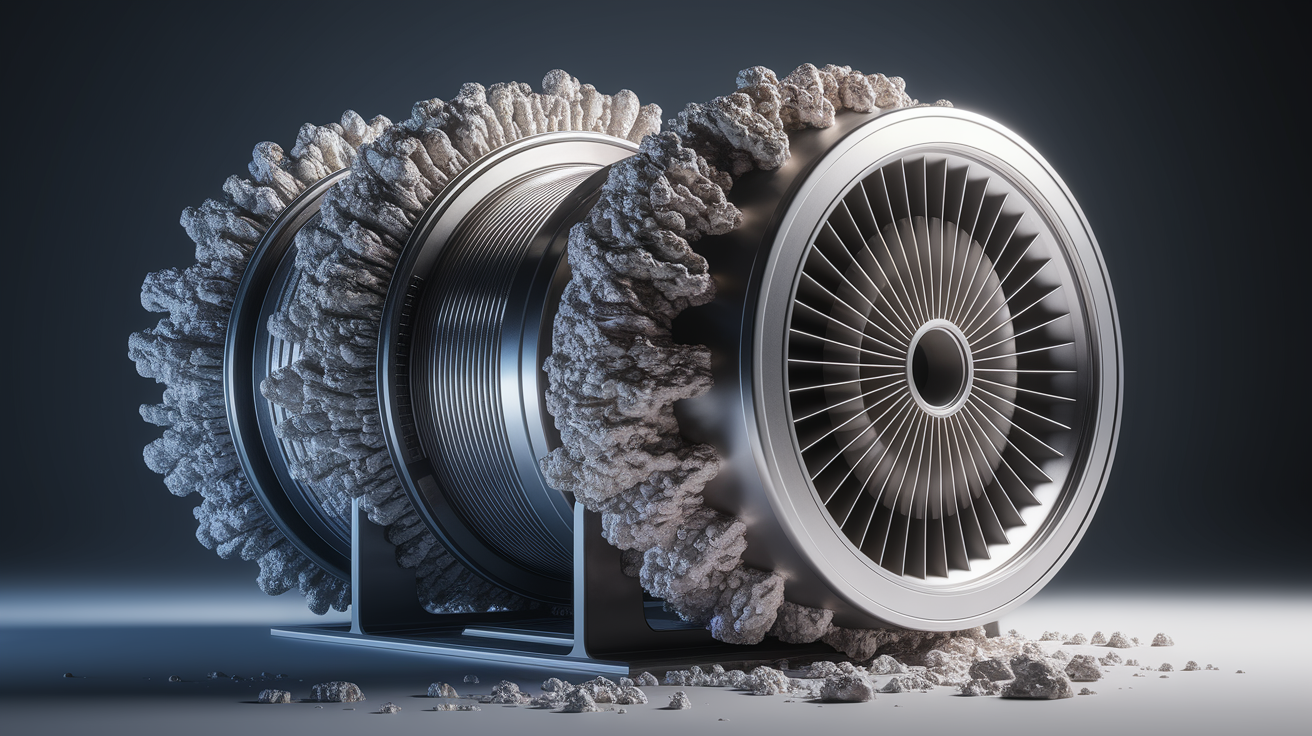

Mineral Buildup and Heat Exchanger Blockages

Hard water containing high levels of calcium and magnesium creates one of the most common long-term problems for tankless water heaters. Limescale buildup affects tankless water heaters by coating the heat exchanger components, reducing their efficiency and potentially causing the unit to overheat and shut down as a safety measure.

Signs of Mineral Buildup

- Decreased water flow from hot water fixtures

- Fluctuating water temperature

- Strange noises from the unit during operation

- Error codes indicating overheating or flow issues

Prevention and Solutions

Understanding how water quality impacts your plumbing is crucial for maintaining your tankless system. Regular descaling using manufacturer-approved solutions can remove existing buildup, while installing a water softener prevents future accumulation.

DIY descaling process:

- Turn off power and gas supply to the unit

- Connect descaling pump and solution reservoir

- Circulate descaling solution for 45-60 minutes

- Flush thoroughly with clean water

- Restart the system and test operation

Fuel Supply Interruptions in Gas Units

Gas-powered tankless water heaters depend on consistent fuel delivery to maintain hot water production. When gas supply issues occur, the result is immediate loss of hot water, often without warning.

Common Gas Supply Problems

Insufficient Gas Pressure: Your tankless unit requires specific gas pressure to operate correctly. If other gas appliances are running simultaneously, or if your gas line is undersized, pressure may drop below operational requirements.

Venting Issues: Improper ventilation can cause the unit to shut down as a safety measure. Blocked vents, damaged vent pipes, or inadequate fresh air supply can all interrupt gas combustion.

Gas Line Problems: Sediment buildup in gas lines, corroded fittings, or kinked flexible connectors can restrict gas flow. These issues often develop gradually, making them harder to identify initially.

Safety Considerations

Gas-related issues require professional attention due to safety risks. If you smell gas, hear unusual sounds from the unit, or notice the pilot light frequently going out, contact a qualified technician immediately.

Electrical and Ignition Failures

Both gas and electric tankless units rely on electrical components for operation. When these systems fail, the result is often complete loss of hot water or intermittent operation that mimics other problems.

Electric Unit Issues

- Heating Element Failure: Electric units use multiple heating elements that can fail individually, causing reduced heating capacity

- Control Board Problems: Faulty control circuits can cause erratic operation or complete shutdown

- Temperature Sensor Malfunctions: Incorrect temperature readings can cause premature shutdown or inadequate heating

Gas Unit Ignition Problems

Gas tankless heaters depend on electronic ignition systems that can experience various failures. Ignition issues often trigger specific error codes that help identify the problem.

Common ignition-related problems include:

- Dirty or damaged flame sensors

- Failed ignition transformers

- Clogged burner orifices

- Faulty gas valves

Environmental and Installation Factors

External factors and improper installation can significantly impact tankless water heater performance, leading to unexpected cold water episodes.

Temperature-Related Issues

Extreme Cold Weather: Freezing temperatures can affect both water supply lines and the unit itself. Some tankless heaters have freeze protection modes that may temporarily interrupt hot water delivery.

Inlet Water Temperature: During winter months, incoming water temperature drops significantly, requiring the unit to work harder to reach set temperatures. This increased demand can overwhelm undersized units.

Installation Problems

Undersized Units: A tankless heater that’s too small for your household’s hot water demand will struggle during peak usage, resulting in temperature fluctuations and cold water interruptions.

Poor Location: Units installed in unheated spaces or areas with poor ventilation may experience operational problems, especially during extreme weather.

Inadequate Electrical Supply: Electric units require substantial electrical capacity. Insufficient electrical supply can cause reduced heating capacity or complete shutdown.

Quick Troubleshooting and When to Call a Professional

Before calling a technician, you can perform several diagnostic steps to identify common issues:

DIY Troubleshooting Steps

- Check water flow: Test flow rate at multiple fixtures to identify pressure issues

- Examine error codes: Note any displayed error messages and consult your owner’s manual

- Inspect venting: Ensure outdoor vents are clear of obstructions

- Test other gas appliances: Verify adequate gas supply throughout your home

- Clean inlet filter: Remove and clean the unit’s water filter if accessible

When to Call a Professional

Contact a qualified technician if you encounter:

- Gas odors or suspected gas leaks

- Electrical issues or repeated circuit breaker trips

- Error codes that persist after basic troubleshooting

- Problems requiring component replacement

- Issues with venting or gas line modifications

Understanding how tankless water heaters function with their automatic flow sensors and safety systems helps you recognize when professional intervention is necessary versus when you can resolve the issue yourself.

Preventive Maintenance Schedule

Monthly:

- Test unit operation and check for error codes

- Clean showerheads and faucet aerators

Annually:

- Professional inspection and cleaning

- Descaling treatment (more frequent in hard water areas)

- Vent system inspection

- Filter replacement

Final Thoughts: Keeping Your Showers Warm and Worry-Free

Dealing with a tankless water heater that goes cold mid-shower can be frustrating, but understanding the common causes puts you in control of the solution. Most issues stem from flow rate problems, mineral buildup, fuel supply interruptions, or component failures that are preventable with proper maintenance.

The key to reliable hot water lies in regular maintenance, proper sizing for your household’s needs, and addressing problems early before they become major failures. While some troubleshooting can be done yourself, don’t hesitate to call a professional when safety is a concern or when the problem exceeds your comfort level.

Remember that expert solutions and preventive measures can keep your tankless system running efficiently for years. With proper care and attention, you can enjoy consistent hot water and avoid those unwelcome cold shower surprises.